- Home

- Policies

- METI Quick Reads

- Green Steel for Green Transformation (GX)

Green Steel for Green Transformation (GX)

What is Green Steel for GX?

We all want to contribute through our daily lives to preventing climate change. Up to now, our main options have included saving power, observing the 3Rs (reduce, reuse, and recycle), and using renewable energy. From now on, the choice of materials such as steel will also become increasingly important. Let’s look at Green Steel for GX.

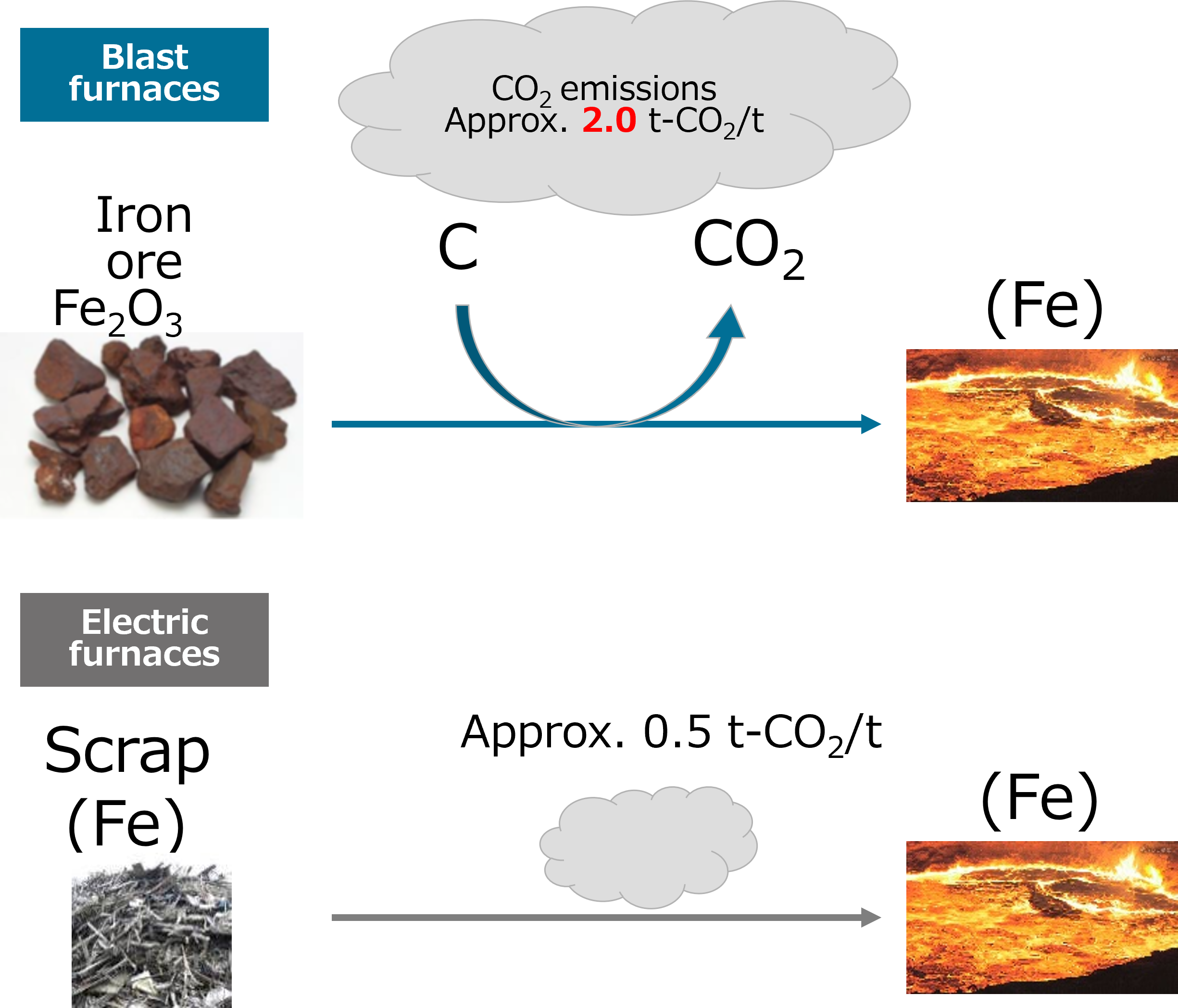

Blast furnaces and electric furnaces: two ways to make steel

The blast furnace process, which uses imported iron ore and coal, produces high-quality steel products, but also emits large amounts of CO2. The steel industry accounts for 13% of all CO2 emissions in Japan. An alternative is the electric furnace process, which uses scrap iron. However, the supply of scrap iron is limited, and the resulting products tend to contain impurities.

CO2 generated by steel manufacturing processes

According to an analysis by the International Energy Agency (IEA), even in the Net Zero 2050 scenario, steel produced from steel scrap will account for only half of the total steel supply. Achieving a carbon neutral society requires GX-inspired ways to reduce emissions in the blast furnace process.

Finding value in lowering CO2 emissions

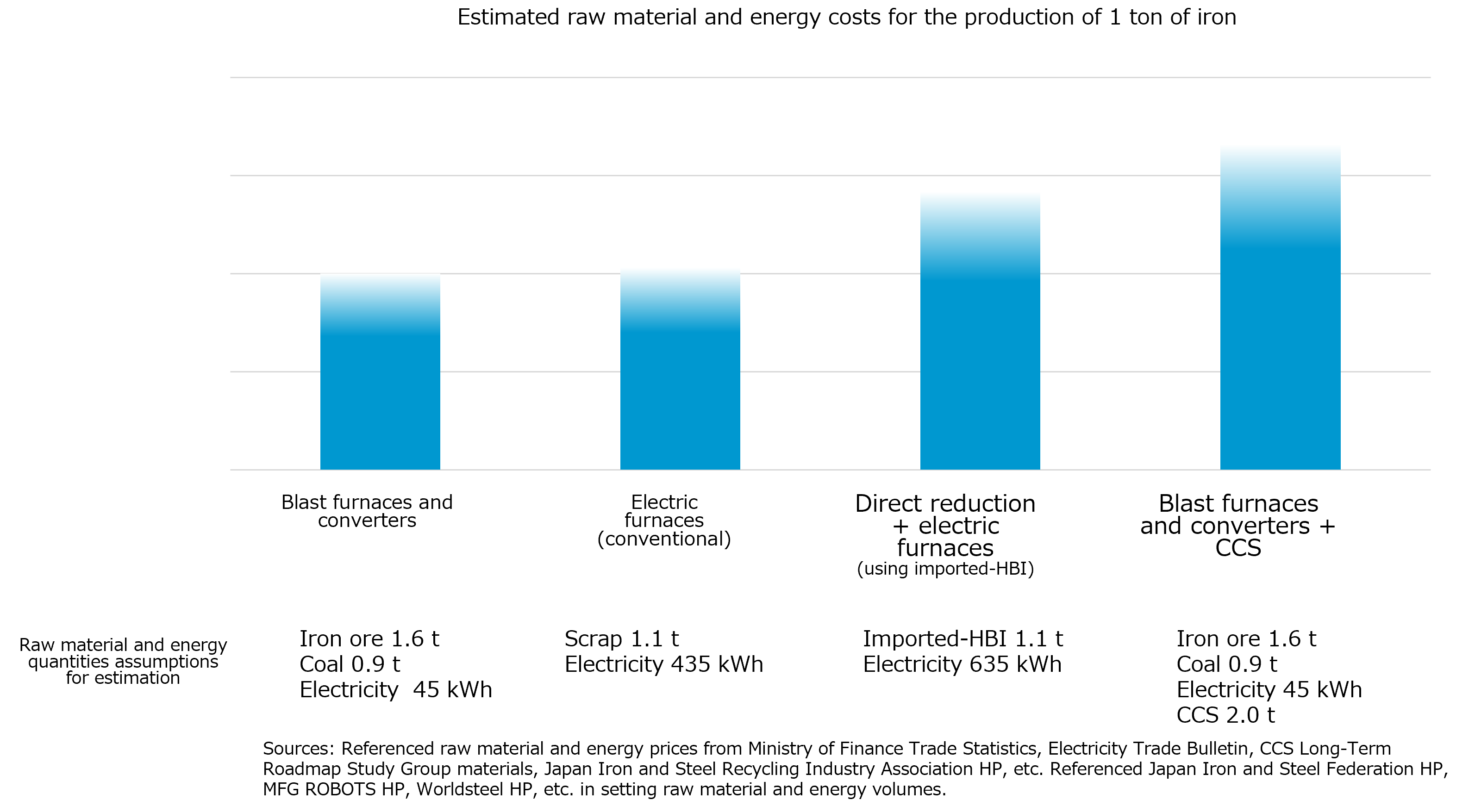

Green steel is the name given to steel made with greatly reduced levels of CO2 emissions compared to conventional processes. It can be produced even with blast furnaces through various methods, including by the use of hydrogen, but in all cases significant capital investment is required. The raw materials and energy costs also tend to be higher than standard approaches.

Estimated raw material and energy costs for the production of 1 ton of iron.

(Referenced raw material and energy prices from Ministry of Finance Trade Statistics,

the Electricity Trade Bulletin, CCS Long-Term Roadmap Study Group materials,

the Japan Iron and Steel Recycling Industry Association website, etc.

Referenced the Japan Iron and Steel Federation website, MFG ROBOTS website,

and the Worldsteel website, etc., in setting raw material and energy volumes.)

To promote GX in light of this situation, we need to expand the market of Green Steel for GX and encourage consumers to choose it despite the significant cost premium. Europe is already striving to reduce CO2 emissions in the process of making products such as storage batteries and automobiles and erecting buildings through measures to utilize green steel as far as is possible.

Choosing Green Steel for GX to contribute to decarbonization

Japanese steel manufacturers have made efforts to reduce CO2 emissions through large-scale capital investment based on technology developments up to now. To promote the use of Green Steel for GX thus created, in 2025 the Government of Japan started initiatives to incentivize manufacturers of end products, such as through the Green Procurement Law and subsidies for clean energy vehicles (CEVs).Japan is taking the first steps toward building a platform able to help decarbonize the industrial sector through mindful choices by consumers inspired by efforts of manufacturers disclosing the use of Green Steel for GX in their end products.

Division in Charge

Metal Industries Division

Ministry of Economy, Trade and Industry

Last updated:2025-12-03